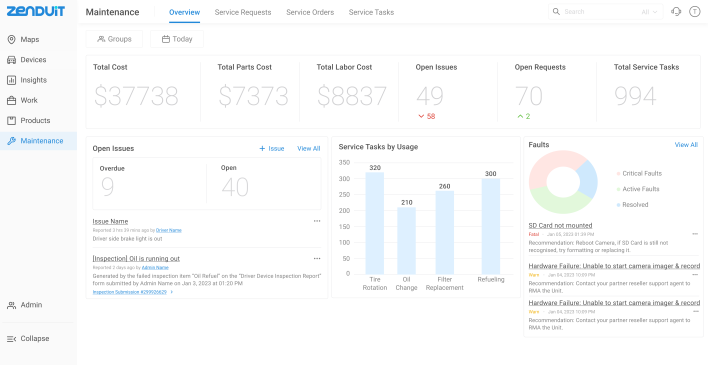

Proactively track equipment usage to gain better insight into the performance and health of critical equipment while identifying issues like failing batteries and engine fault codes to maximize safety and performance of vehicles.

Tailor-Made Features

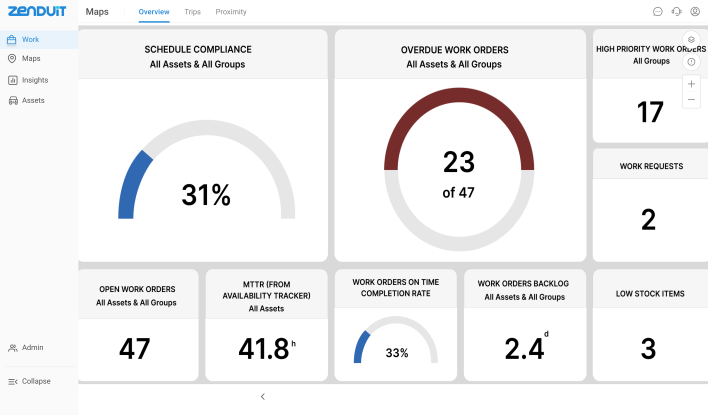

Extend asset lifecycles, control costs and utilize resources, with solutions that enable automation, IoT data, analytics and AI into your maintenance strategies.

Prevent Unplanned Breakdowns

Proactively testing and analyzing Diagnostics report

Efficient Maintenance Scheduling

Efficient plan resources allocation like tools and replacement parts more efficiently with reports and maintenance alerts.

In-depth Reporting

Utilize Reports and Fleet Maintenance Systems ECM Readings to allocate resources better.

Real-time Vehicle Diagnostics for Faster Daily Pre and Post Trip Checks

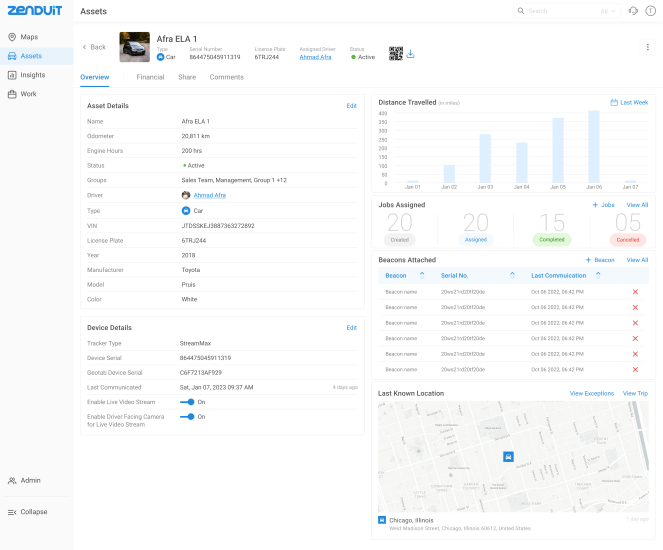

Streamline Your Workflow

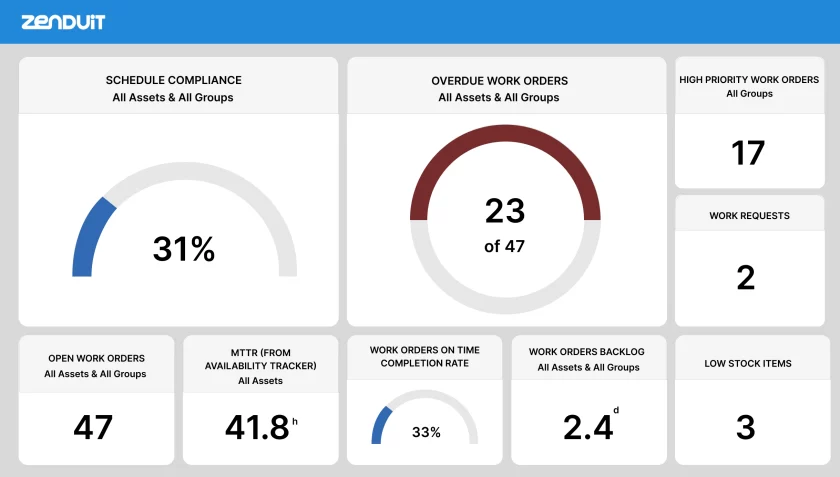

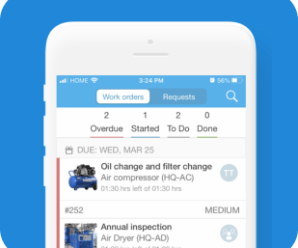

Visualize and prioritize your work orders with customized dashboard to get In-depth overview of your work orders, including high-priority tasks, overdue work orders, and KPIs

Insights on Your Entire Fleet

Monitor all of your heavy-duty vehicles and calculate health and safety scores based on the faults in all components.

How it works?

Here’s how you can streamline your Work Order Management Process.

01

01

Conduct Daily Pre-trip checks. Find faults and leaks in the vehicle.

02

02

The maintenance manager is notified and assigns the work order to a technician.

03

03

Set up a work order in the system and assign it to a mechanic. See the work order in maintenance calendar.

04

04

The mechanic gets an alert and completes the work order. Pre-trip check passes.

Featured Products

View AllOur Telematics Solutions

Explore all our solutions that make it simple to manage your fleet.